Company profile

The company Gilles Tooling was founded in 2005 and produces various attachments for the motorcycle industry according to the highest standards. These include chain tensioners, footrest systems, brake and clutch levers and protectors.

In addition to private customers and retailers, the company’s customers include big names such as BMW, Yamaha, KTM, Suzuki and Polaris. The company is based in the Potaschberg industrial estate in the municipality of Grevenmacher and currently employs around 70 people. Their main activities lie in the research and development and manufacturing divisions. The latter is the area in which a large part of the electricity and heat costs originate.

Idea

Eliminating compressed air leaks with the aid of an ultrasonic camera

Due to the ongoing fluctuations in energy prices, manufacturing companies are naturally striving to control these costs as much as possible and to optimise energy savings.

To this end, the company has examined its compressed air supply and concluded that there is considerable potential for energy savings. Compressed air is needed at every machine and at every workstation in production: predominantly for the fully automated milling machinery, but just as well for other processes such as cleaning, degassing or assembly.

The analysis showed that the continuous expansion of the production has led to a very complex compressed air network, which regularly incurs losses through leaks.

Because production operates continuously around the clock, and there is an inherent noise level in the production hall, it is not possible to audibly identify any leaks through hissing noises. Consequently, it became evident that an alternative solution was needed to identify any potential leaks.

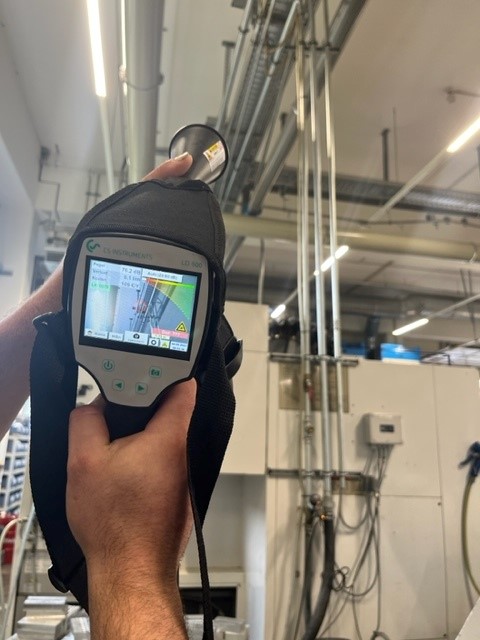

Following research, a conclusion was reached that an ultrasonic camera would be the appropriate solution.

Design

Exchange with the House of Sustainability

The company got its first information on financial support on guichet.lu. For the acquisition of the device, which amounted to a four-digit sum, they were able to draw on the financial support of the “SME Package – Sustainability” programme. With the help of the House of Sustainability, they were able to prepare their application file in a very objective and uncomplicated manner. This included soliciting offers, completing the application and obtaining the approval message from the House of Sustainability. The contract could then be issued.

Implementation

Employing an ultrasound camera

The device is easy to operate and allows the compressed air network to be inspected while the machines remain running. The camera shows an ultrasound image of the plant, on which one can see the location and extent of the leakage. Based on the resulting data, it is then possible to assess how quickly a response is needed.

The ultrasonic camera is used for both suspected leaks as well as regular maintenance of the compressed air supply.

Results

Savings on electricity bills

According to the company’s internal calculations, the cost of one cubic metre (1 m3 ) of compressed air is about 3.38 cents. At a network pressure of 8 bar, approximately 4.5 m3/h (15.21 cents) would leak from a breach of 1 mm in diameter.

Based on the company’s experience and on the leaks that have already been detected and repaired, this results in an estimated loss of 100 m3/h. This leads to losses of 3.38 €/h and a total of around 30,000 € over an entire year.